UAE

SHARJAH

OBJECTIVE

This project involved the full replacement of 792 HID Luminaires. The luminaires were 250W High Pressure Sodium. After a full onsite review and lighting design to show the current light levels, the King of the Road P862 and P863 luminaires were selected to for the roadway lighting. The P863 luminaires were used on the smaller 6m columns around the Mosques.

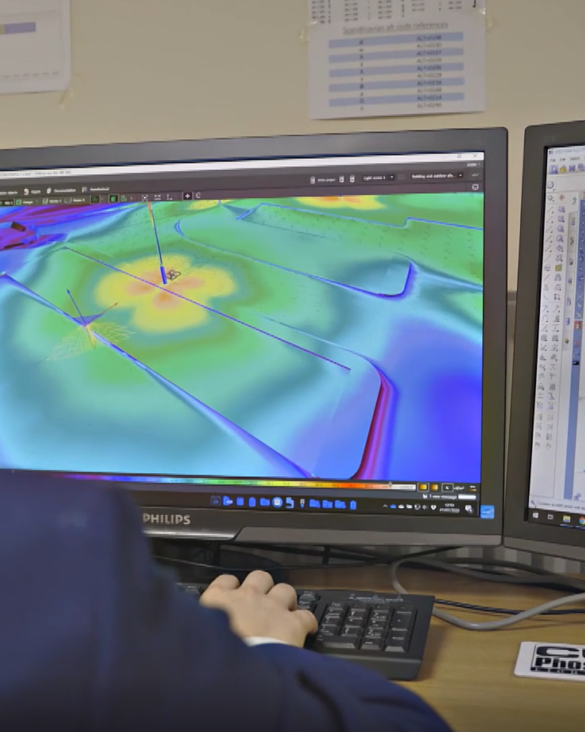

CU Phosco worked very closely with SEWA Engineers Roa’a AlKhatib and Afra Al Owais throughout the initial planning process. They both made the whole project very easy and enjoyable to complete. After 2 onsite light level checks to check the light levels that were being achieved by the incumbent HID luminaires. Following on from this CU Phosco’s in-house lighting designers completed numerous lighting designs to show how the light levels can be achieved for the all the different road geometries present in the two areas. The two engineers were fantastic in supporting CU Phosco in the absence of a Bill of Quantities and any CAD Drawing to complete the lighting designs. They worked tirelessly throughout their evenings to complete a full count of the luminaires required and measurements of the road geometry. This allowed the lighting designers to complete the designs efficiently and accurately.

My experience in working with CU Phosco was very positive. Their professionalism was refreshing. And I as part from SEWA lighting team, would welcome the opportunity to work with them again

Mariam Binkhadim

Sharjah Electricity & Water Authority (SEWA)

SOLUTION

Once all lighting designs were complete CU Phosco presented a proposal to SEWA that in turn was presented to HE Dr Rashid Alleem (Chairman of SEWA). Once approval was granted to proceed by, HE Dr Rashid Alleem, CU Phosco began production.

As part of the product approval process SEWA engineers Roa’a, Afra and Mariam visited our manufacturing facility in Hertfordshire to carry out a FAT’s test (Factory Acceptance Test). This allowed them to assess our production processes, quality procedures and discuss delivery logistics of the program. All parameters were surpassed in this evaluation.

The program forecast was structured for one full delivery of luminaires to the installing company in Sharjah, UAE. Production took 10 weeks to complete followed by 5 weeks shipping time. Haji Commercial Company LLC then completed the full installation of all 792 luminaires in 4 weeks to ensure SEWA were gaining the benefits of the energy efficient lighting as soon as possible.

Working with Cu Phosco was a pleasure. They did a great job of supplying and installing LED streetlights in Al Tarfa and Al Darari. We look forward to work in future projects with them”

Mariam AlZarooni

Sharjah Electricity & Water Authority (SEWA)

The LED scheme has provided a white light solution increasing visibility on the road and therefore improving road user’s awareness and subsequent safety. By selecting the latest technology SEWA have achieved a huge energy saving whilst improving the asset and reducing the required maintenance.

Working in collaboration CU Phosco, SEWA delivered a well-structured and smooth transition of change with little to no disruption to local residents. Striving to improve our customers experience and responding to feedback is a key part of the collaboration process. This project is a testament to the value that working partnerships can provide. CU Phosco look forward to working with SEWA on future projects to continue to provide the latest technology to the residents of Sharjah.

The impact of retrofitting Al Tarfa & Al Darari Area’s was very positive on the society of both neighbourhoods. With the support of CU Phosco, we were able to deliver those results

Roa’a AlKhatib

Sharjah

RESULTS AND BENEFITS

Street lighting is one of the main focuses in Sharjah Electricity and Water Authority (SEWA). The use of LED streetlights is growing continuously due to their greater energy efficiency, robustness, long life and light control. In addition, the vision of His Highness Sheikh Sultan Al-Qassimi the ruler of Sharjah, is to make Sharjah the city of conservation so energy saving, and retrofitting is a top priority. Hence SEWA planned to start changing from Sodium street lighting to energy efficient LED lights. The goal is to improve the level and quality of road lighting by implementing LED technology, in order to save energy, reduce maintenance cost also to offer customers better lighting quality with suitable color selection.

The starting point of this project was assigning two residential areas (Al Tarfa and Al Darari), surveying the existing lights, measuring distances and calculating lux levels. Project awarded to Cu-Phosco and the streetlights order was placed. For quality assurance and auditing purpose, three engineers from SEWA were involved to inspect the manufacturing process for the patch by checking mechanical, electrical soldering and fixing LED chips. After the supply and installation, site inspection completed, and the new lux levels were measured. The results showed great improvement and energy saving. It was noticeable that after retrofitting to the new efficient LEDs more than 80% of the houses outdoor lighting were switched off which also helped in reducing the energy consumption.