Much of the technology that keeps us safe on UK roads works invisibly in the background – smart sensors, adaptive signals, and dynamic signage all help to manage traffic without us even noticing. However, when it comes to road tunnels, there is no room for subtlety: as a safety-critical environment (especially in the event of an accident or breakdown), lighting plays a uniquely visible and vital role.

Whether a short urban underpass or a longer, high-speed tunnel through the countryside, lighting must do far more than illuminate. It needs to reassure, guide and protect - ensuring visibility, supporting driver confidence, and helping to prevent sudden braking that can lead to collisions.

WHY TUNNEL LIGHTING MATTERS

At many key locations in the UK road network, especially where bottlenecks are likely, good lighting makes a measurable difference to safety and traffic flow. In tunnels, where conditions can change in an instant, that difference becomes critical.

Tunnels are natural pinch points. The goal is therefore straightforward: to keep traffic moving smoothly, reduce queueing, cut emissions, and, above all, maintain safety.

But getting lighting right in a tunnel isn't simple. It takes specialist expertise and precision design to ensure drivers can see clearly and react quickly – in any conditions.

Fortunately, there's a wealth of global and national guidance available to support tunnel lighting design.

Internationally, the CIE 88-1990 standard (revised in 2004) from the International Commission on Illumination sets out best practices for modern road tunnels. In the UK, this is complemented by BS 5489-2:2016. For short tunnels (defined as those under 150m long), you can also find additional guidance in the form of the PLG09 document from the Institution of Lighting Professionals (ILP).

THE CIE APPROACH: SIX KEY ZONES

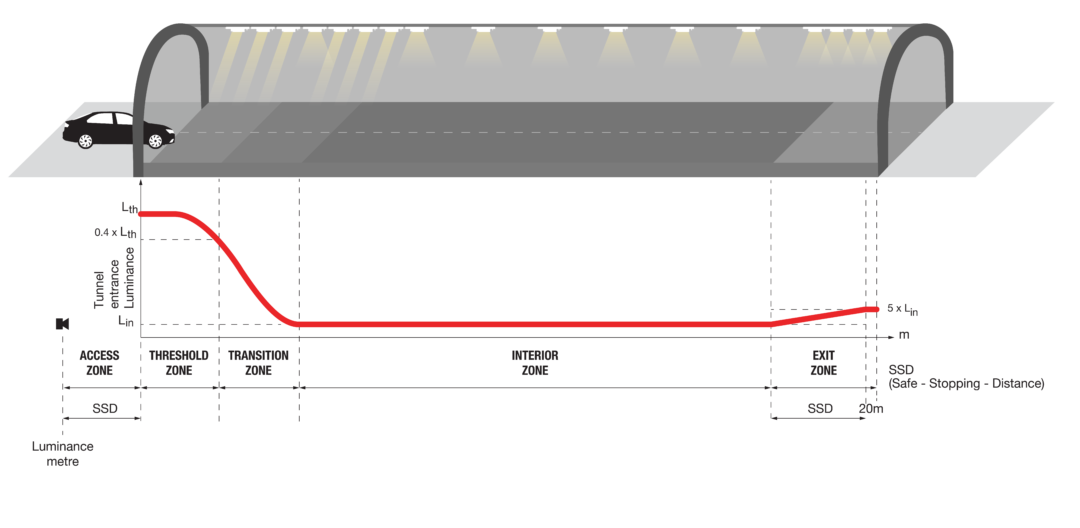

The CIE guidance categorises tunnel lighting into five core zones, plus a sixth "parting" zone located beyond the tunnel exit. Each zone tailored to ensure smooth visual adaptation for drivers moving between the brightness of daylight and the relative darkness of tunnel interiors.

ACCESS ZONE: The road leading up to the tunnel entrance. It must be at least equal in length to the stopping distance - the thinking and braking time needed by a driver to come to a halt under prevailing road conditions. Drivers must be able to see clearly into the tunnel, detect obstacles, and enter safely without reducing speed.

THRESHOLD ZONE: Equal in length to the stopping distance, the threshold zone should feature a high, constant luminance level, allowing for visual adaptation. By the end of this zone, the luminance can be reduced to 40% of the initial value.

TRANSITION ZONE: Here, luminance levels should be reduced progressively to match the levels required in the interior zone. The rate of reduction is time-based and linked to the human eye's capacity to adapt. The zone ends when luminance reaches three times the level of the interior zone.

INTERIOR ZONE: Typically, the longest section, this zone sits between the transition and exit zones. Lighting levels are intrinsically linked to vehicle speed and traffic density.

EXIT ZONE: As drivers approach the exit, their vision is influenced by the outside brightness. While the eye adapts quickly from low to high light, additional lighting may be required — especially if the exit is not visible or in cases where the tunnel is used for two-way flow during emergencies or maintenance. This zone is limited to 50m and features luminance levels up to five times higher than the interior zone.

PARTING ZONE: Located outside the tunnel, this zone supports safe re-adaptation to daylight. It's typically twice the stopping distance in length and should be factored into the overall lighting scheme.

TUNNEL LIGHTING SYSTEMS

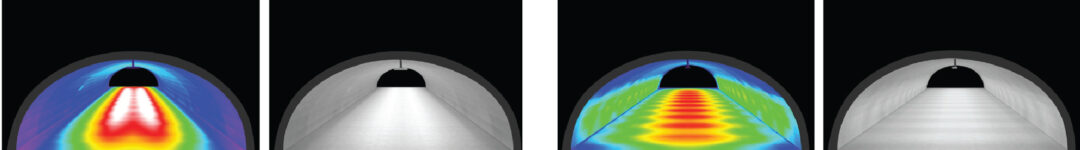

Tunnel lighting designs use three core lighting strategies, utilising either ceiling-mounted (above lanes), and/or wall-mounted luminaires depending on tunnel layout:

- SYMMETRICAL LIGHTING: Light is distributed evenly in both directions along the traffic flow, offering balanced visibility of road surfaces and vehicles.

- COUNTER-BEAM LIGHTING: Light is directed against the traffic flow, enhancing contrast and object visibility in the direction of travel—a common choice for tunnels with higher traffic volumes or speeds.

- PRO-BEAM LIGHTING: Light is directed in the same direction as traffic flow, useful in certain geometric or safety scenarios.

STRIKING THE BALANCE: SAFETY, COST AND ENVIRONMENTAL IMPACT

If tunnel lighting is so crucial, why not simply flood the tunnel with high-powered (1500W) lights and be done with it? The reality is more nuanced.

While safety is always the top priority, lighting design must also balance financial and environmental responsibilities. Overlighting may seem like a simple solution, but it dramatically increases energy consumption and installation complexity, and results in more frequent maintenance over time, meaning greater carbon emissions.

That’s precisely why modern standards like BS 5489-2:2016 and CIE 88 exist - not to add complexity, but to define optimal lighting levels that keep drivers safe without unnecessary overspend or environmental burden.

Well-designed systems aim for full compliance with fewer luminaires, reducing capital costs, installation time, power consumption, and environmental footprint. The best solutions deliver maximum safety with minimum waste - better for budgets and better for the planet, while keeping roads lit, efficient, and sustainable.

ENVIRONMENTAL AND IMPACT RESILIENCE

Tunnel lighting systems must also be tough. Not only must they function reliably in emergency conditions, but they also have to resist long-term exposure to some of the most demanding environmental stressors on the road network.

Ingress Protection (IP) ratings must account for humidity, moisture, and corrosive environments - especially near coastal areas.

Chemical exposure is significant: tunnels trap residues from fuels, oils, vehicle exhausts, de-icing salts, and cleaning detergents - all of which can degrade components over time.

Impact Protection (IK) ratings are important, too, ensuring luminaires can withstand knocks and vibrations from high-speed traffic or maintenance operations.

Crucially, because wind and rain don't naturally clean tunnel interiors, and maintenance can be infrequent or impractical due to operational and cost reasons (closing a tunnel is detrimental to surrounding route congestion) - luminaires must perform well over long periods without intervention.

PROVEN TECHNOLOGY

One tunnel lighting solution already proven in challenging environments is GOLEDO, developed by tunnel lighting specialist Heper. It combines adaptive lighting with high-performance materials and flexible configurations to meet global and local standards.

Key Features of GOLEDO Tunnel Lighting:

- Advanced Optical Design: Customisable distributions for seamless light transitions and optimal visual comfort.

- Built to Withstand the Harshest Conditions: Engineered using materials resistant to heat, humidity, impact, and corrosive chemicals.

- Compliance with Global and National Standards: Designed to meet stringent requirements for safety, efficiency, and reliability.

- Easy to Install and Maintain: Modular cable tray and ceiling-mount brackets simplify installation and reduce downtime during servicing.

- Flexible and Efficient: Adjustable power options and lighting distributions tailored to each tunnel's unique needs.

- UK-Specific Design Expertise: Provided through CU Phosco/Heper’s exclusive partnership for the UK and Ireland.

For UK road authorities, that means: Access to a global tunnel lighting specialist with high-profile reference projects, while enabling seamless integration of tunnel lighting into wider road lighting schemes (a specialist area for UK manufacturer CU Phosco). By working with a single provider, customers benefit from streamlined procurement, local support, and simplified maintenance.

READY TO LIGHT THE WAY

GOLEDO adaptive lighting technology offers a globally proven solution that meets UK standards, including BS 5489-2:2016, and delivers the performance, safety, and reliability required in today's road tunnels.