In the world of exterior lighting, reliability isn’t optional—it’s essential. Whether illuminating motorways, parks, industrial estates, or residential streets, galvanised steel lighting columns offer unmatched performance, longevity, and peace of mind. These zinc-coated columns are engineered to thrive in the harshest outdoor environments, making them the smart choice for modern lighting infrastructure.

WHY CHOOSE A GALVANISED COLUMN?

Corrosion Resistance: Built for the Outdoors

Exterior lighting columns are constantly exposed to moisture, pollutants, and temperature extremes. Galvanised steel combats these threats with a protective zinc coating that shields the steel from corrosion. Even better, the zinc corrodes sacrificially (known as cathodic protection) meaning it protects the steel beneath by taking the hit first. This makes galvanised columns ideal for coastal zones, urban centres, and rural installations alike.

Long Lifespan: Lighting That Lasts

Hot-dip galvanised lighting columns can deliver more than 50 years of service in average environments and 20–25 years in areas of severe water exposure. That’s decades of dependable illumination with minimal upkeep—perfect for councils, contractors, and developers looking to future-proof their infrastructure.

Cost-Effective: Invest Once, Illuminate for Years

While galvanising may carry a higher initial cost than some coatings, the long-term savings are undeniable. Reduced maintenance, fewer replacements, and extended service life mean lower total cost of ownership. For public lighting schemes and large-scale infrastructure projects, that’s a budget-friendly win.

Durability: Engineered for Real-World Conditions

Lighting columns must withstand wind loads, mechanical stress, and environmental wear. Galvanised steel delivers the strength needed to support luminaires, brackets, and accessories—without compromising structural integrity. Whether flanged or rooted, these columns are built to endure.

Low Maintenance: Set It and Forget It

Once installed, galvanised lighting columns require little to no ongoing maintenance. No repainting. No sealing. There is no maintenance required. The increased durability of the steel's finished product also increases the product's reliability. Just reliable performance year after year. That’s a major advantage for local authorities and facility managers tasked with maintaining large lighting networks.

Versatility: One Column, Many Applications

Galvanised steel columns are compatible with a wide range of luminaires, brackets, and mounting heights—making them suitable for:

- Street lighting

- Car parks

- Industrial estates

- Public spaces

- Sports grounds

- Highways and motorways

GALVANISED COLUMNS FROM CU PHOSCO

From 3m to 12m, CU Phosco’s column range—including Stepped Tubular, Mid-Hinged, and Tapered Tubular designs—offers flexibility and performance tailored to your lighting needs.

CU Phosco columns are available in a variety of finishes and are backed by a team of technical experts. Every column is:

- Designed to BS EN 40 standards

- UKCA approved

- Built for a 25-year design life

- Custom Finishes and trusted standards

SUSTAINABILITY: LIGHTING WITH A CONSCIENCE

Galvanised steel is fully recyclable and built to last, making it a sustainable choice for eco-conscious infrastructure projects. Fewer replacements mean less waste and a smaller environmental footprint.

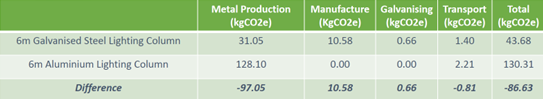

Much to people’s perception Galvanised steel columns are far more environmentally friendly than their aluminium counterparts as the table below suggests:

Whether you're upgrading urban lighting or planning a new development, galvanised steel lighting columns offer the strength, reliability, and longevity your project demands. With CU Phosco’s proven range, you’re not just installing lights—you’re building lasting infrastructure. See the full range of lighting columns here