CU PHOSCO'S APPROACH

At CU Phosco, we are committed to creating a more sustainable future and believe the circular economy is becoming an increasingly important model to achieve this. The circular economy is a system where resources are used to their fullest extent to minimise waste and pollution. Lighting's impact on resource scarcity and climate change has become a growing concern in outdoor lighting, as the rise in LED lighting has unwittingly created 'fit and forget' luminaires, fuelling the industry’s ingrained linear model of consumption.

In 2021, the Society of Light and Lighting (SLL) published the CIBSE Technical Memorandum 66 (TM66) to tackle some of the issues at play. It outlines what it means to design and manufacture products that comply with circular economy principles. It includes a checklist, a method of assessing a product's circular economy performance, and real-world examples of good practice. At CU Phosco, we believe that the awareness and adoption of TM66 are essential to the continued advancement of environmentally responsible design and manufacturing, but we also need to be realistic about its limitations. Let's delve deeper into how we got here.

THE MOVE TO LED LUMINAIRES

Over the last decade, the lighting industry has been focused on in-use lighting energy efficiency. This has resulted in the rapid adoption of LED luminaires, significantly reducing energy consumption. However, the shift to LED has also resulted in three unintended consequences. Firstly, the "fit and forget" product - with little or no provision to replace the light engine or driver on failure. This meant that when a luminaire had an individual component failure, it had to be replaced with a new one, with the original luminaire's raw materials being disposed of through a WEEE recycling scheme, with the added value of manufacturing being lost in the process. Secondly, the rate of product development in LED luminaires made product life cycles shorter and more complex. The availability of spares and the ability to identify and source compatible spares that match the performance of a five-year-old installation were challenging. Thirdly, the "offshoring" of product production further limited the availability of spares or the ability to re-engineer used luminaires.

DESIGNING AND MANUFACTURING FOR A CIRCULAR ECONOMY

At CU Phosco, we believe that designing and manufacturing for a circular economy is essential to secure a sustainable future. Our product design and development process has always focused on principles that are now recognised as those required for circularity. We routinely evaluate our products for their circular economy performance. Presently, our key product ranges are designed to be accessible for maintenance, modular and upgradeable, with replaceable parts, and we have taken great care in selecting materials that can be recycled or reused.

The quality and robustness of our products are at the heart of our approach. We understand that designing for circularity requires a long-term view and a commitment to quality to prevent as far as possible those early component failures. Our return rates for our products are incredibly low, which is a testament to their quality and reliability.

CIRCULAR PRINCIPLES AT PLAY

One of the classic examples of circular economy as a philosophy is our work with Royal Borough of Kensington and Chelsea. Over the last 45+ years we have provided our P109 luminaire to light the communities of the Borough. The original luminaires were sold with low pressure sodium lamps, and as technology has improved we have upgraded these through high pressure sodium lamps, ceramic metal discharge lamps, Cosmopolis lamps, and then early LED retrofits. Most recently we are providing our latest heritage retrofit solution providing a further significant energy saving compared with the original LED solution. Each upgrade retained the existing luminaire body and changed only the light source and control gear on their mounting plates ensuring luminaires were only replaced when they reached the end of their useful life.

Similarly in Kent, CU Phosco has provided approximately 88,000 LED luminaires over two years. As is the case with all electronics, we expect a small number of early driver failures and we are collaborating with Bouygues and Kent to recover these luminaires, rework them in our factory in Ware, and complete full product safety testing before returning the repaired luminaires to the contractor as replacement stock for future failures.

WHERE DOES TM66 FIT IN?

Before TM66, it was difficult for a buyer to compare the circularity of products from different manufacturers as they all had their own unique methods of measurement. TM66 provides practical guidance to all in the lighting industry, at every level and all sizes, to create a circular economy in the lighting industry. At CU Phosco, we are committed to designing and manufacturing for a circular economy.

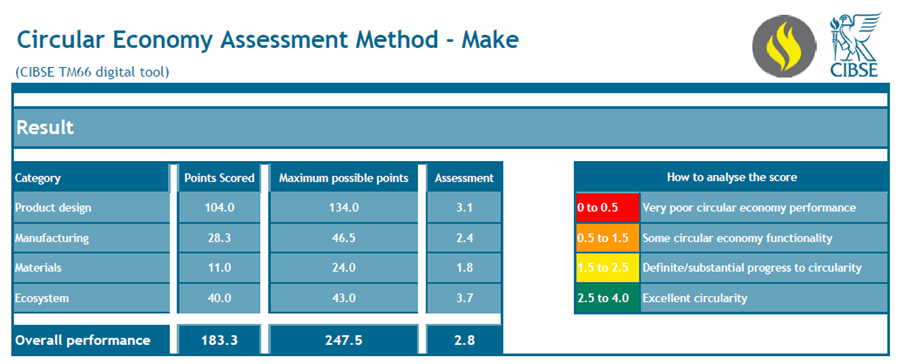

One of the most practical takeaways from TM66 is the Circular Economy Assessment Methods (CEAM), specifically the CEAM-Make and CEAM-Specify tools. They aim to provide manufacturers and specifiers with a detailed understanding of a product's circular economy performance. The CEAM-Make assessment is a comprehensive tool covering all aspects of product design, manufacturing, materials, and supporting ecosystem, with a score from 0 to 4. The CEAM-Specify tool, on the other hand, is a quick triage tool that allows buyers to ask the most important questions of manufacturers, making comparisons between two or more products easier.

CEAM IN PRACTICE

Having worked closely with some of the contributors to TM66 at CU Phosco, we have embraced the CEAM-Make tool and have assessed our popular P86 range of road lighting luminaires. The range scored an industry-leading 2.8 on the assessment, indicating excellent circular economy performance (some two or more points higher than most other competitors). As demand for this type of information grows amongst our customers and potential specifiers, we plan to assess further product ranges. The CEAM-Specify tool is also proving to be a valuable resource for our clients, allowing them to make more informed decisions by asking the most important questions of manufacturers and comparing products more efficiently.

THE FUTURE OF CIRCULAR ECONOMY TOOLS

As the circular economy gains momentum, we expect more tools like CEAM to emerge, helping manufacturers and clients make more informed decisions and driving innovation towards a more sustainable future. However, it's important to note that while TM66 provides a common ground, it is a voluntary model and not mandatory. Although it offers a low-cost and accessible measurement, some companies still use their own measurement tools and techniques, making it challenging to compare sustainability metrics across the industry.

THE LIMITATIONS OF SUSTAINABILITY METRICS

It's worth noting that sustainability is complex; the more we look into products, materials, and processes, the more impacts we will have. TM66 is designed to balance complexity with effectiveness and usability but relies on its user's intelligence. At CU Phosco, we believe that a circular economy approach is good for the environment and our customers. By designing products following the principles and common sense we have been applying for a century, we hope to contribute to a more sustainable future and continue to reduce waste.

Overall, CEAM and similar tools provide an important step towards greater environmental sustainability and transparency in the manufacturing industry. As more companies adopt circular economy principles and standardised metrics, we can preserve our natural resources, night sky and natural habitats for a greater future for all.

David Lodge CEng MICE MIEAust CPEng – Technical Director